By using the given rotational speed of 1800 rpm input power of 10 horsepower gear ratio of 35 and an overload factor of 15 the rough dimensions of the gear and pinion were determined. New Design of the Automobile Automatic Gearbox Providing Driving Simplification and Driver Fatigue Decrease.

What is gearbox or transmission.

. There are no great advances in gear technology described. Types Of Automobile Gearbox Working of Sliding Mesh Gearbox. Study and Sectional View of Differential Gear- Mechanical Projects.

Design and Fabrication of Progressive Gearbox Report Download. 5 Issue 08 2017 ISSN online. A typical case would involve the design of the gearing for a hoist to raise a certain weight W ata uniform speed when making use of a motor with a given horsepower hp run-ning at a given speed rpm and driving through a pinion with number of teeth Np Fig.

Gearbox Design Machine Design- Interview Question and Answers. AUTOMOBILE ENGINEERING CONTENTS Chapter Topic Page no. Also facilitates change of direction of output shaft for reversing Automotive gearboxes are used to reduce load on the engine by manipulating torque and speed.

The word transmission is used for a device that is located between the clutch and the propeller shaft. Volume 20 2017 Pages 544-549. Locate and secure components in an appropriate manner and in their proper position.

By operation of the brakes and one-way clutches either the planetary carrier or the planetary sun gear is immobilized altering the speed of revolution of the planetary. The strength design of the gear to allow for the use a Grade 1 steel. At present much is known about gear load-carrying capacity and many complicated processes for making gears are available.

And planetary sun gear. 5 15 Components and Nomenclature 6 16 Engine support systems 12 161 Cooling system. Up to 24 cash back With these major changed to the design the gearbox is still operating well and safely according to the theoretical calculations.

The gear lever operated by the driver is connected to a series of selector rods in the top or side of the gearboxThe selector rods lie parallel with shafts carrying the gears. While the transmission is in gear as engine speed increases torque is transferred from the engine to the input shaft by the motion of the fluid propelling the vehicle. Gearbox in automobile.

Gear box finds its application in Agitators conveyors crushers cranes elevators feeders small ball mills mixers cooling towers Extruders Packaging and Filters. Introduction and Purpose Provides speed and torque conversions because of the limitations of internal combustion engines. It has three shafts.

Small gear driving large gear Under Drive Under Drive happens when Carrier is the Output Under drive increases Torque decreases Speed Large Gear driving Smaller gear Overdrive Overdrive happens when the Carrier is the Input. 3 14 Resistances to vehicle motion. Introduction to Gear Design Introduction Albert Einstein once said.

Each of the chapters will deal with a-specific problem which is encountered during the design phases and during operation. Things should be made as simple as possible but no simpler This book is an attempt to apply that principle to gear design by presenting information from a manufacturing point-of-view rather than a theoretical one. This system was used as a baseline to which other designs were compared.

The most popular design is the constant-mesh gearbox. Whenever the rotary motion encounters bearings are required to support the revolving part and reduce the friction. 2321-0613 Automobile Transmission Systems Suyash Galgale1 Prathamesh Deore2 Ketan Pardeshi3 123 BE Student 123 Department of Mechanical Engineering 123 University of Pune Nasik India Abstract In the current world of automobile gear shifting equipped with an.

System Design 21 Powertrain layouts The previous powertrain design consisted of two Emrax 228 motors each with a chain drive single gear reduction to independently drive the rear wheels. It may be a gearbox a torque converter overdrive fluid drive or hydraulic drive. O In automotive applications the pump typically is connected to the flywheel of the engine The turbine is connected to the input shaft of the transmission.

In the gear box both counter and main shaft are. Different Types Of Automobile Gearbox. In the design of gear teeth to transmitand use the power.

A small car gear box contains four speed gear ratio and one reverse gear. This chapter begins with a comparison of the merits of spiral bevel gears and hypoid gears when employed as the final drive in the automotive gearbox ix. This type of gearbox increases the lifespan of your equipment and optimizes performance.

Gearbox Design Layout only Gearbox Design Issues. Planetary gearboxes come in either a solid type of hollow format or with a variety of mounting options including a flange shaft or foot. At the very least the same setup could be used but.

Design of a manually operated automotive gearbox. Rotating Elements ie gears sprockets pulleys etc 3. Holistic approach involving design manufacturing testing packagingshippinghandling installation operation and maintenance.

Gears are mainly typed like spur gears helical gears double helical gears bevel gears crown gears hypoid gears worm gears. It also involves almost all stakeholders gearbox OEMs turbine OEMs ownersoperators research institutes governmental agencies and so on. When the engine is running and the car is stopped the stator will lock on the One Way Clutch.

Gear design is a highly complicated art. The input shaft the layshaft and the mainshaft which run in bearings in the gearbox casing. UNIT - I - VEHICLE STRUCTURE AND ENGINES 11 Introduction to Automobile or Vehicle 1 12 Types of Automobile 2 13 Vehicle construction and Components.

Power from the engine transmitted the input shaft via the torque converter is than transmitted to the plan-etary gears by the operation of the clutches. Different types of gearbox in automobile are described below. IJSRD - International Journal for Scientific Research Development Vol.

A gear is a rotating machine part having a cut tooth which meshes with another toothed part in order to transmit torque. DESIGN OF AN AUTOMOTIVE DIFFERENTIAL WITH REDUCTION RATIO GREATER THAN 6. The constant pressure to build less expensive quieter running lighter and more powerful machinery has resulted in a steady change in gear designs 3.

Each detection technique has its own advantages and limitations. Up to 24 cash back 2.

How A Gearbox Transmission Works What S Gear Ratio Carbiketech

Pdf Direct Gear Design For Automotive Applications

Design And Fabrication Of Gear Box Full Report Download

Visualization Of Gearbox Design Parameters Variables Description In Download Scientific Diagram

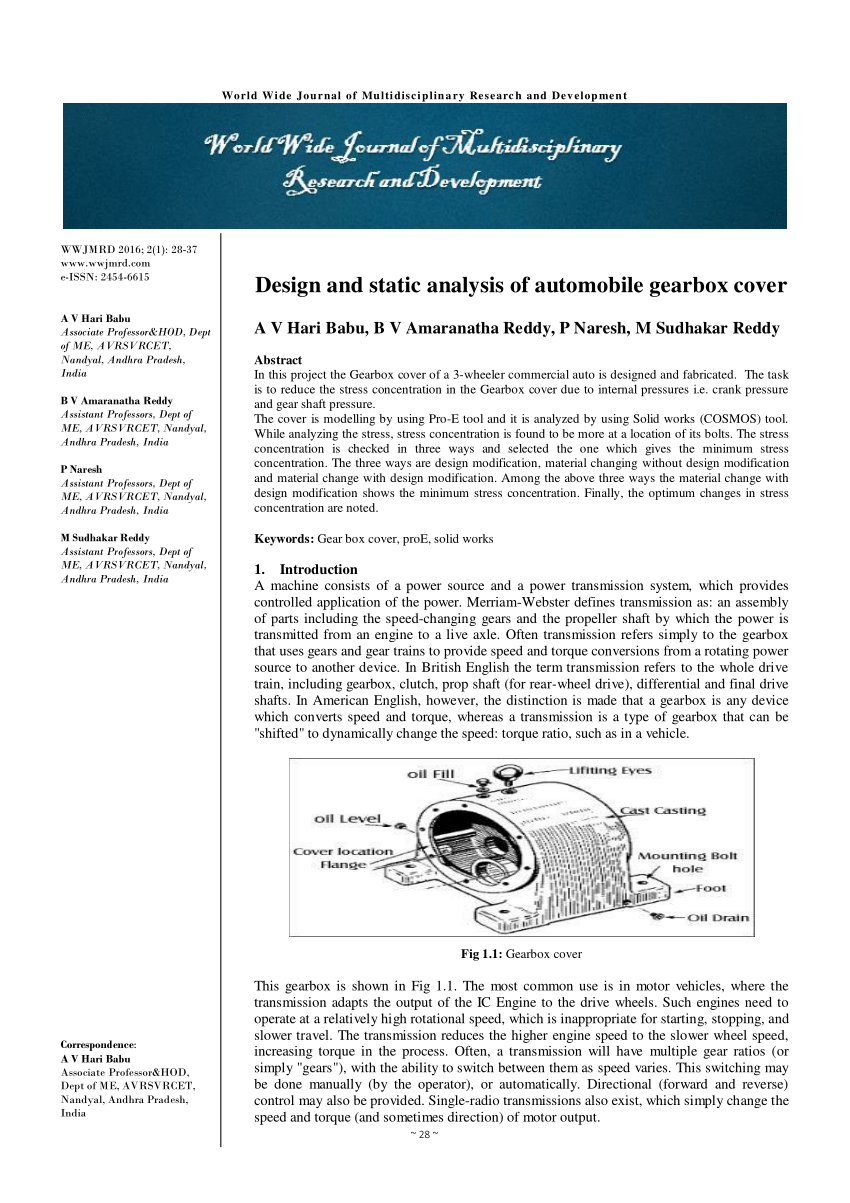

Pdf Design And Static Analysis Of Automobile Gearbox Cover

0 comments

Post a Comment